At its core, a 3D scanner is a powerful tool that meticulously creates an accurate digital copy of a physical object or environment. It does this by collecting three-dimensional data about its shape and, in some cases, its appearance (such as color). This model can be manipulated or edited using software or even brought to life through 3D printing. With that out of the way, let's look at the fascinating world of 3D scanners and explore why they are so widely used.

What Do People Use a 3D Scanner For?

The versatility of 3D scanners is truly remarkable. They find applications in a wide range of fields, from reverse engineering and product design to 3D printing, AR/VR, e-commerce, quality control, industrial prototyping, healthcare solutions, custom motor vehicle modification, and more. The possibilities are endless.

Why Do People Use Them?

The key reason for using a 3D scanner is its ability to save significant amounts of time and money. It provides the fastest and most accurate way of creating a model with the correct dimensions, eliminating the need for manual measurements and potential errors. This practical value is what makes 3D scanners a game-changer in various industries.

Sure, you can use a ruler, caliper, and protractor to measure an object manually and build it in CAD software. However, depending on its size and complexity, that can take hours or even days, often resulting in incorrect measurements. So, rather than wasting a ton of time, 3D scanner users can achieve their end goal with minimal fuss.

What Kind of 3D Scanners Are There?

There are five major types of 3D scanning solutions available.

Structured Light - 3D scanners that use structured light typically have an infrared or blue light projector and two IR cameras on either side that detect the deviation of the geometric light patterns as they bounce back off the object being scanned.

|

Pros |

Cons |

|

High-precision and resolution |

Doesn’t work in direct sunlight |

|

Relatively easy to get good scanning results. |

They can’t scan huge objects. |

|

Infrared light is suitable for scanning people. |

Scanners can be expensive but have become much more affordable in recent years. |

Laser Triangulation - 3D scanners that use this method project a laser onto an object and then use angled cameras to detect how long it takes the light to return. This type of scanning provides excellent accuracy and resolution, but finishing a scan can take a while, as surfaces must be scanned multiple times to capture them fully.

|

Pros |

Cons |

|

High accuracy and resolution |

Scanners are costly. |

|

Reduces the challenge of capturing dark and reflective surfaces |

Slow scanning speed |

Photogrammetry - Uses a camera to take multiple photos of an object from various angles and then import them into software to combine the images into a 3D model. You can do this right now with your smartphone’s camera. However, the quality of your camera will limit your accuracy, and getting decent 3D models from it can be a fairly complex work process.

|

Pros

|

Cons

|

|

It can scan massive objects like buildings when using a drone.

|

It’s hard to get right

|

|

It is cheap, though accurate scans will require high-end cameras.

|

Requires a powerful computer and specialized software.

|

|

Good quality textures

|

|

Contact - Uses a physical probe that directly contacts the object and moves along its surfaces to scan it. Contact scanners are highly accurate and typically used in industrial applications with a minimal margin of error.

|

Pros |

Cons |

|

Very accurate |

Quite slow |

|

Can scan transparent or reflective surfaces |

It can be complicated to set up. |

Light Detection and Ranging (LiDAR) - This method measures the speed of the light between the object and the scanner’s sensors to measure an object’s surface geometry. You might be more familiar with this one, as from the iPhone 12 onwards, the Pro models have included a LiDAR scanner that, when used with an app, can perform rudimentary 3D scans.

|

Pros |

Cons |

|

Can scan huge objects |

Slow scans |

|

Easy to use |

Less accurate |

While LiDAR can be found in some iPhones, it’s more typically used in more professional large-scale object scanning of homes, building sites, large vehicles, or even geographical features where sub-mm accuracy isn’t required.

What’s the Scanning Process?

Well, that depends on the type of scanner you have, but to simplify it, you use your scanner to scan your object, and this, in turn, creates a point cloud, which is a set of data points in space that represent the shape of the object you scanned.

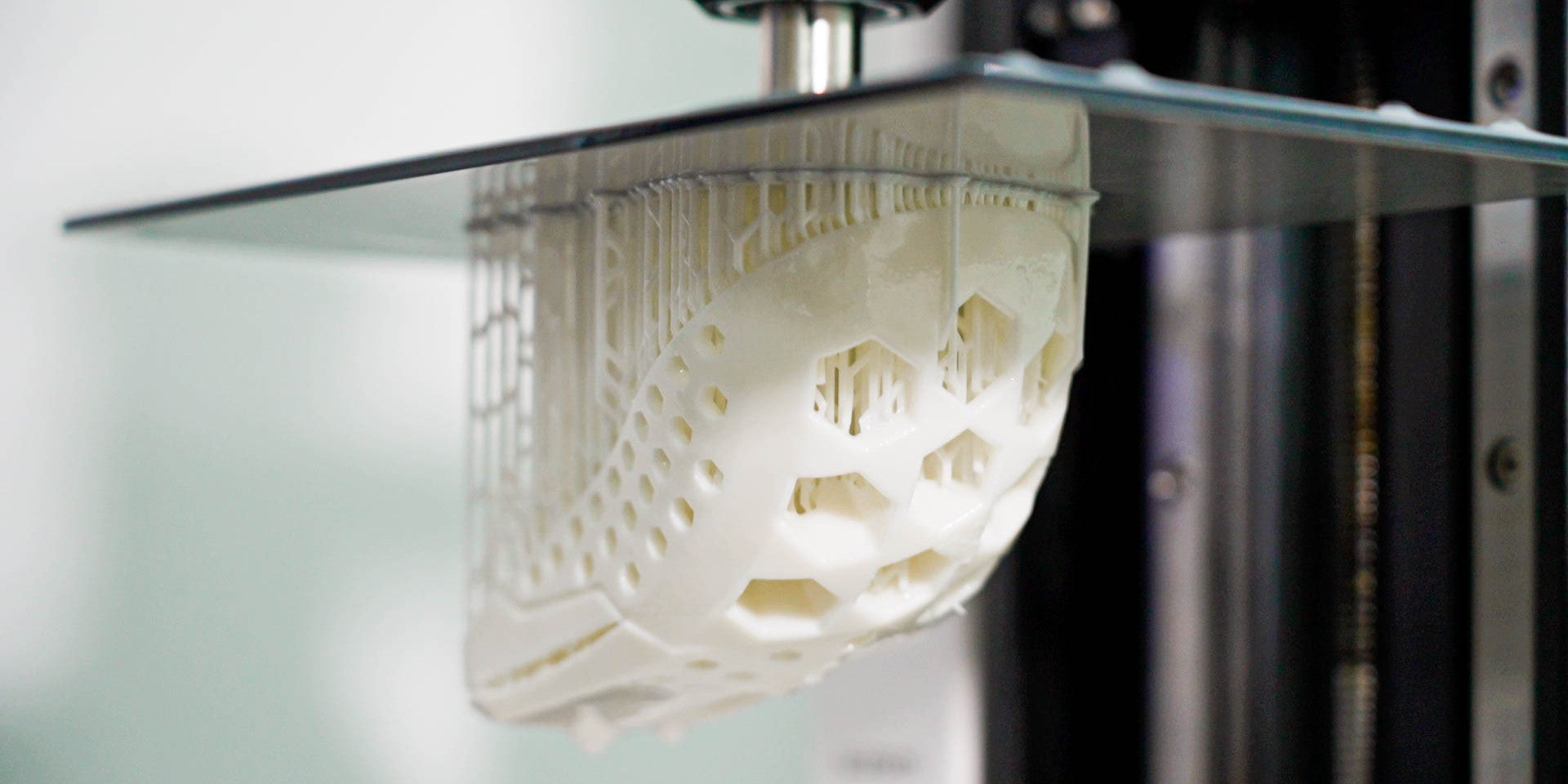

Once you have a point cloud, you convert it into a 3D mesh, which means all the cloud's points are connected to create a 3D surface. At this point, your application determines what you do next. You could load your model into the Unreal engine and use it in a video game or 3D slicer software to prepare it for 3D printing.

How Do I Select a Scanner?

This really depends on the size of the objects you wish to capture. As there are different types of scanners for various sizes of objects, so you must think carefully about what you want to scan before buying a 3D scanner.

Unless, of course, you get the Revopoint MIRACO. It can scan objects from small to large using its advanced quad-depth camera system and offers full standalone processing and editing capabilities for versatile scanning operations.

Learn more about 3D scanning with the help of these handy articles:

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.