Vehicle Modification with Automotive 3D Scanner

Don’t let outdated methods hold you back. Streamline your vehicle-based projects with the help of Revopoint Automotive 3D scanners to optimize your workflows, reduce costs, and save time.

Modifying Vehicles

Traditionally, automobile modeling has involved time-consuming and often inaccurate measurements with calipers and rulers, then manually building a CAD model. Fortunately, this slow process can be vastly sped up with the help of a Revopoint 3d scanner for cars, allowing you to create an accurate 3D model in minutes rather than days.

Modifying Vehicles

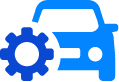

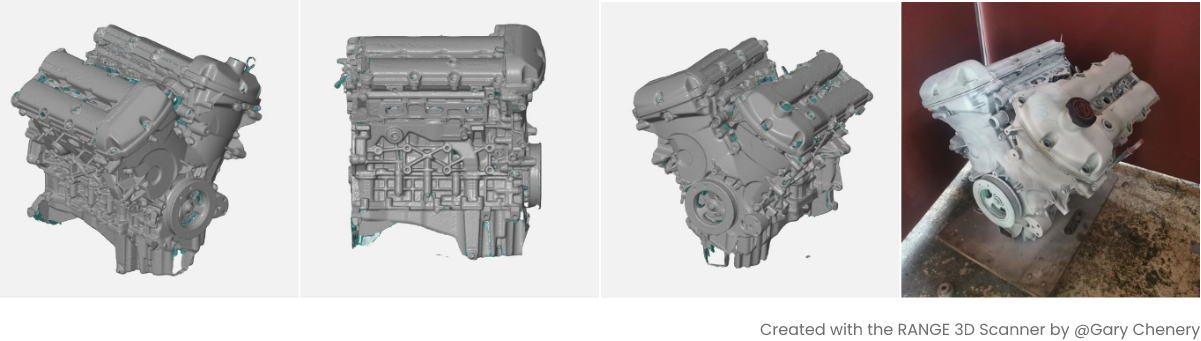

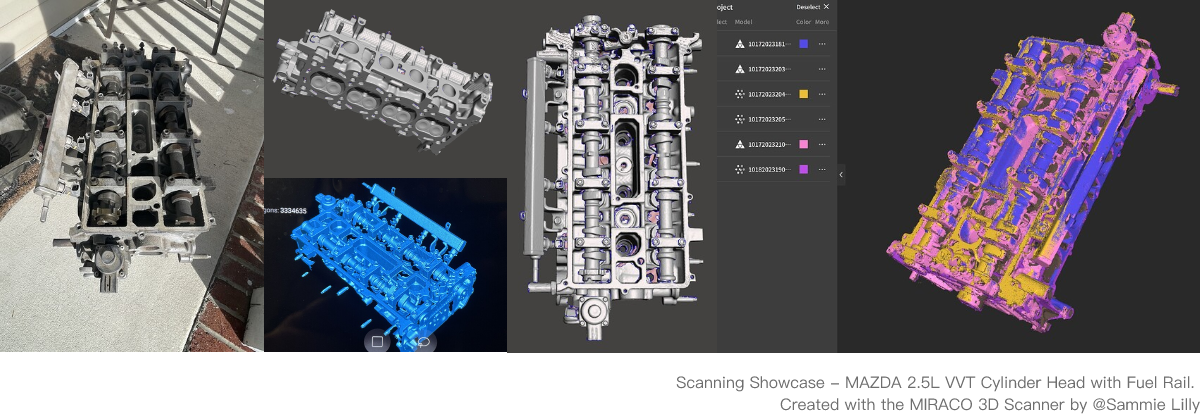

When stock parts aren’t the solution you’re looking for, you need accurate measurements to start the rapid prototyping of new parts for your vehicle. With a Revopoint 3D scanner, you can create accurate 3D models ready for import into CAD software.

Replacement Parts

Finding spare parts to replace interior or exterior parts is a nightmare for vehicles, but with a Revopoint 3D scanner’s help, capturing accurate measurements of parts for reverse engineering or replacement has never been easier.

Quality Control

Revopoint 3D scanners help simplify the process of identifying quality issues in newly created parts. With a quick scan, you can compare the parts against the original CAD design without manual measuring and checking. This not only saves you time but also ensures that you are delivering quality products to your customers.

FAQ

What is a 3D scanner for automotive?

A 3D scanner for automotive is a device used to capture the surface geometry of vehicles and vehicle components, creating detailed digital 3D models. These models are commonly used for vehicle modification, reverse engineering, prototyping, and inspection workflows. Compared with manual measuring methods, a 3D scanner for automotive enables faster data capture and more consistent digital results when combined with suitable software tools.

How does a 3d scanner for cars improve vehicle modification?

A 3D scanner for cars can quickly capture high‑precision 3D models of vehicle surfaces and components, reducing manual measurement errors and speeding up the overall design process. The scanned models, such as PLY, OBJ, or STL files, can be imported into CAD software for reference or reverse engineering, supporting custom part design, test fitting, and production. However, it is important to note that these mesh models are not directly editable solid entities and usually require conversion or re‑modeling within CAD software before further use.

What vehicle parts can be scanned with an automotive 3D scanner?

Automotive 3D scanners can capture a wide range of vehicle parts, including body panels, bumpers, wheels, dashboards, engine components, and interior trim. They support both small detailed parts and larger vehicle sections, making them suitable for custom fabrication and modification projects.

Can automotive 3D scanners be used for custom car parts and prototyping?

Yes, automotive 3D scanners are widely used for custom car part design and rapid prototyping. Scanned data allows designers and engineers to create precise CAD models for custom brackets, mounts, panels, or accessories. These designs can then be manufactured using CNC machining or 3D printing.

How does a 3D scanner help with replacement parts and reverse engineering for vehicles?

A 3D scanner helps with replacement parts by capturing the exact geometry of existing components, even when original design files are unavailable. This supports reverse engineering workflows, allowing damaged or discontinued parts to be recreated with accurate dimensions for proper fit and performance.

What should I consider when choosing a 3D scanner for vehicle modification?

When choosing a 3D scanner for vehicle modification, key factors include scanning accuracy, ability to handle large objects, portability, and compatibility with CAD software. Stable tracking and support for automotive surfaces are also important to ensure reliable results during vehicle based scanning projects.

Recommend 3D Scanners