Advances in 3D optical scanning and robotic integration are transforming large-scale 3D scanning, enabling faster, more reliable digitalizations without disrupting existing workflows, even for objects like a 2.5-meter-tall Italian modern Stele sculpture.

Description: a 2.5-meter-tall Italian modern Stele sculpture scanned by Revopoint Trackit

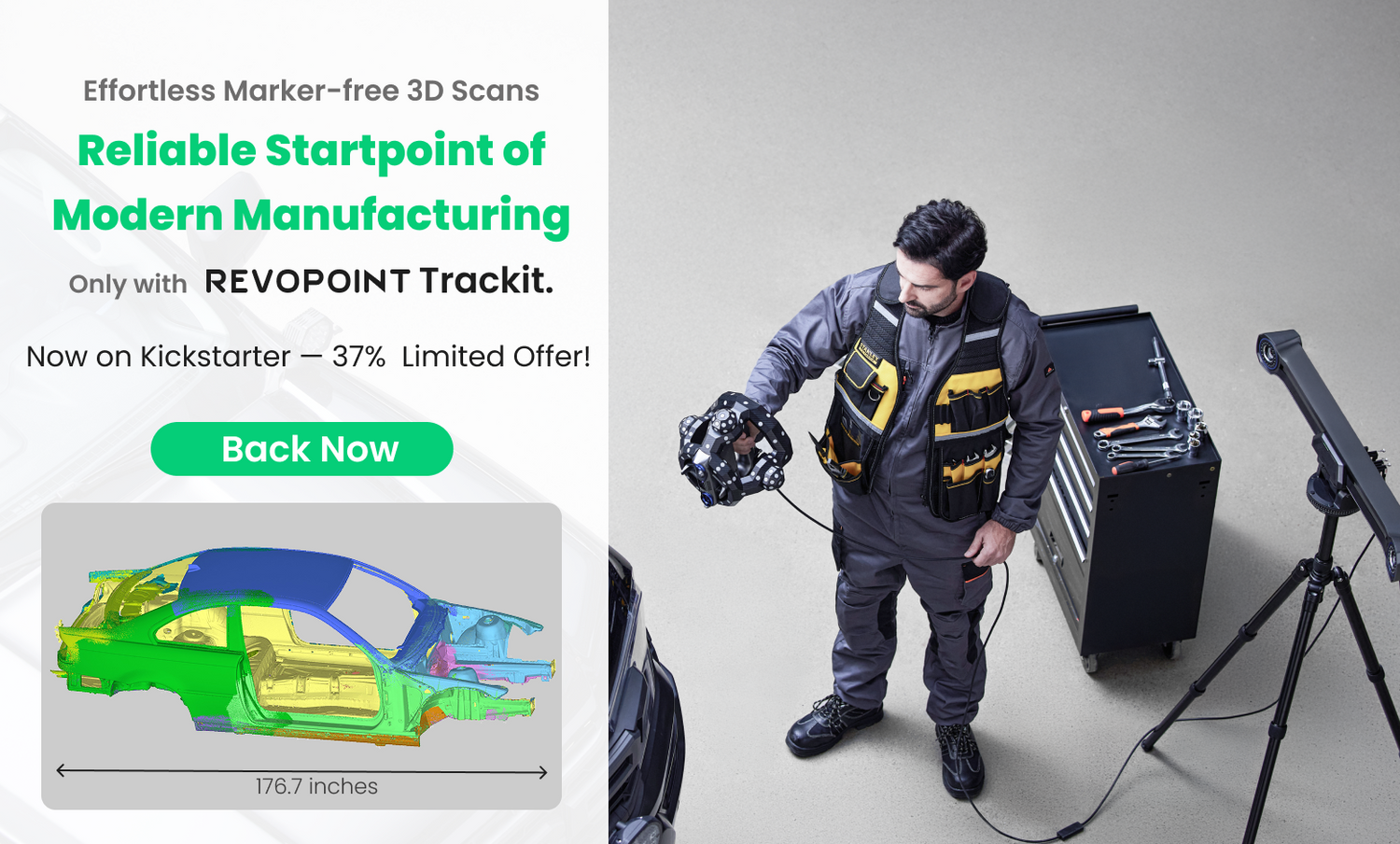

If you work on the shop floor or oversee engineering operations, you know the drill: tighter tolerances, faster turnaround times, and growing part complexity. But inspection hasn’t kept pace. Manual tools, older 3D scanners, and workflows that rely heavily on skilled operators are hindering the industry's progress.

Traditional inspection methods are no longer sufficient. They’re slow, inconsistent, and require too much expert labor. That’s why more teams are switching to automated optical scanning systems paired with collaborative robots, like Revopoint Trackit. These solutions accelerate inspections, provide more reliable data, and scale seamlessly as production demand increases.

Where Traditional Scanning Falls Short

Manual marker placement means scanning sessions can take hours of preparation before you even begin capturing data. Many systems struggle with reflective surfaces, complex geometries, or large objects that exceed their tracking capabilities. The result is often incomplete scans, time-consuming post-processing, and the need for multiple scanning sessions to capture a single object.

Description: Examples of Tracking 3D scanner vs. Non-Tracking 3D scanner

These limitations create real barriers for creators, engineers, and professionals who need reliable 3D data. Whether you're reverse engineering a vintage car part, creating digital assets for film and gaming, or documenting cultural artifacts, traditional scanning workflows can become major bottlenecks in your creative process.

What Advanced 3D Scanning Technology Changes

Modern tracking-enabled 3D scanners address these challenges by combining high-resolution optical sensors with intelligent tracking algorithms. The scanning process becomes more intuitive and comprehensive, requiring significantly less setup while delivering superior results.

For example, marker-free scanning eliminates the need for adhesive targets, cutting down preparation time and keeping parts clean. Drag-to-tech programming enables operators to physically guide the robot arm to create scan paths, eliminating the need for coding. Scanning paths can also be generated directly from CAD models, reducing programming time while ensuring critical features are covered.

Description: A Metric and Standard Nut and Bolt Gauge Scanned by Revopoint Trackit

Proven by Media, Experts, and Users

But don’t just take our word for it. The advantages of Trackit’s large-scale, marker-free 3D scanning have not only been recognized internally but also validated by media, experts, and real-world users.

And a huge thanks to all our amazing backers. Our beta testers have been putting Trackit through its paces! From high-precision part inspections to full-body car scans, they're demonstrating the power of Trackit for both professionals and creators alike.

Leading media like Voxel Matters, 3DPrinting, 3DVF, and 3DWithus have highlighted how Trackit’s automated calibration and dual scanning modes significantly improve efficiency and accuracy across a wide range of object sizes.

Description: Star Wars droid scanned by Revopoint Trackit, about 44cm/17 inches tall.

Industry professionals have also demonstrated Trackit’s versatility — from scanning the full stripped body of a BMW E46 coupe, capturing intricate details of a crown grill, to reverse engineering highly reflective cast alloy parts.

Description: A frame of a BMW E46 coupe Scanned by Revopoint Trackit

User feedback confirms these strengths. Lajos Turi, founder of Modception, notes that Trackit dramatically reduces preparation time, sometimes cutting project durations nearly in half. R&D technician Johnathan appreciates that Trackit eliminates the need for markers or special features, simplifying the scanning process and reducing costs. Sammie Lilly, founder of SkreetKar3D, values Trackit’s high-resolution and precise scans, which streamline workflows across automotive, machining, engineering, and DIY repair projects.

Why This Matters

From an operations standpoint, the benefits are clear. Faster inspection results in shorter lead times and improved throughput. With less dependence on highly skilled labor, manufacturers can better manage staffing challenges. Reliable and repeatable data support traceability, compliance, and continuous process improvements. Because these systems are modular, they often integrate into existing production lines without costly overhauls.

Automation for the Real World

The push for more efficient, reliable quality control has been a key driver in the development of these automated scanning solutions. William Zhou, CEO of Revopoint, shared insights into the philosophy behind creating one of such systems – Revo. "Our aim was to break down the traditional barriers of complexity and expense that kept automated, high-precision QC out of reach for many manufacturers. We focused on building a system where the entire inspection process, from positioning to scanning and data analysis, could be streamlined, repeatable, and require minimal manual intervention."

Description: Revopoint Trackit Robot 3D Scanning System fully automates repetitive 3D scanning tasks

This vision highlights the creation of accessible tools such as the Revopoint Trackit and Trackit Robot 3D Scanning System, designed for modern manufacturing. It combines a compact, high-accuracy optical tracking 3D scanner with a collaborative robot, supporting programming methods like drag-to-teach, CAD-driven paths, and real-time vision guidance.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.