In a world where precision, speed, and digital transformation drive innovation, 3D scanning has emerged as an essential technology across industries. Whether you’re a designer, engineer, artist, or manufacturer, understanding the basics of 3D scanning and how it enhances the way we capture, replicate, and analyze real-world objects can give you a competitive edge. In this in-depth guide, we’ll explore how 3D scan technology works, its core methods, practical applications, and what makes modern solutions like those from Revopoint stand out.

What Is 3D Scanning?

3D scanning is the process of digitally capturing the physical shape and surface details of real-world objects to create precise, three-dimensional models. These digital replicas—often called point clouds or meshes—form the foundation for tasks like reverse engineering, product inspection, 3D printing, and digital archiving.

The process involves projecting light or lasers onto an object and using sensors to record the reflected data from multiple angles. This data is then processed by specialized software to reconstruct an accurate 3D model that can be measured, edited, or manufactured.

How Does 3D Scanning Work?

Modern 3D scanning solutions employ a variety of technologies, each with its unique strengths:

Structured Light Scanning: Projects a pattern of light onto the object. Cameras capture how these lines deform, and software calculates the object’s geometry. This method is known for speed and high accuracy, suitable for most small-to-medium objects.

Laser Scanning: A laser sweeps across the surface while sensors record the reflected light. This method is ideal for capturing intricate details or scanning larger areas, including industrial or architectural applications. For example, the Revopoint MetroX 3D Scanner utilizes advanced laser scanning technology to deliver precise and efficient results for a wide range of professional scenarios.

Photogrammetry: This method uses multiple photographs taken from different angles, with software triangulating features to create a 3D mesh. While not as precise as structured light or laser scanning, photogrammetry is accessible and effective for certain applications. For example, the MIRACO Plus is the first standalone 3D scanner with integrated photogrammetric metrology capabilities, enabling more accurate and versatile 3D capture in a portable device.

Contact Scanning: Mechanical probes physically touch the object to record data points, primarily used in high-precision industrial metrology.

Each method results in a digital model comprising millions of coordinates (vertices), forming a point cloud that depicts the object’s shape. These points can be further processed into polygonal meshes for CAD, 3D printing, or visualization.

Why Is 3D Scanning Important?

3D scanning bridges the physical and digital worlds, unlocking new possibilities in design, manufacturing, and creativity. Some of the most impactful benefits include:

Time Savings: Rapidly digitize complex shapes, eliminating manual measurement and modeling.

Accuracy & Repeatability: Capture fine details and maintain consistent results—critical for quality control, inspection, and reverse engineering.

Versatility: Adaptable to objects of all sizes and materials, from jewelry and dental molds to automotive parts and historic artifacts.

Digital Workflows: Seamlessly integrate with CAD, CAM, and 3D printing, streamlining prototyping and product development.

Common Applications of 3D Scanning

The versatility of 3D scan technology is reflected in its broad range of applications:

Reverse Engineering: Digitize existing parts for product redesign, replacement, or legacy documentation Learn more about reverse engineering.

Aerospace: Quickly scan aircraft components to check for wear, fatigue, or to create precision replacement parts Explore aerospace solutions.

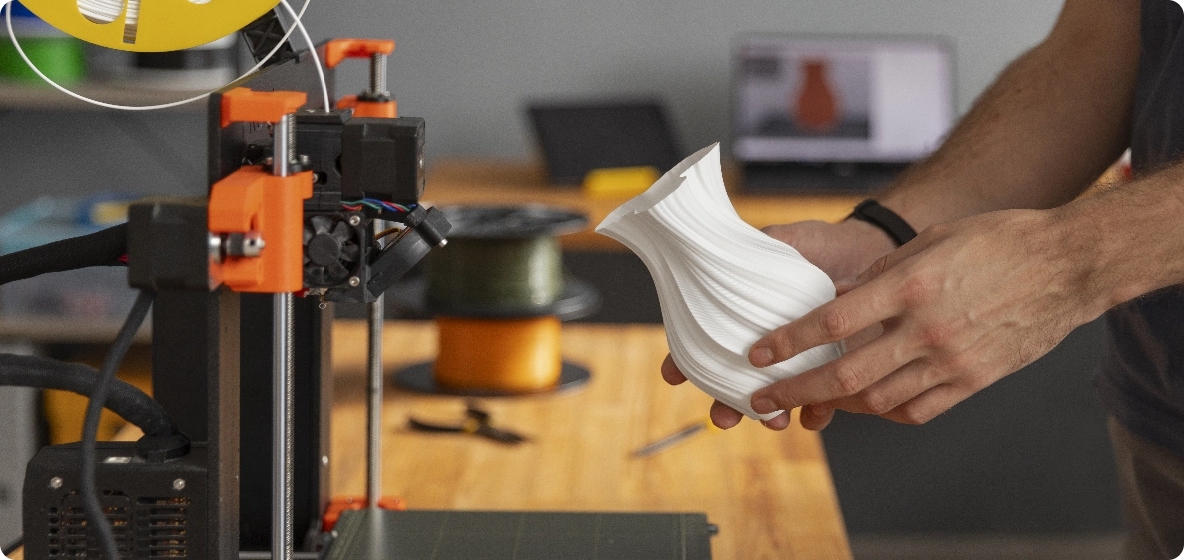

3D Printing: Convert physical objects into printable digital models, accelerating prototyping and small-batch manufacturing Explore 3D printing solutions.

Vehicle Modification: Precisely measure vehicle components for custom parts or performance upgrades Explore vehicle modification applications.

Healthcare: Create personalized prosthetics, orthotics, and dental appliances from accurate body scans. Explore healthcare solutions .

Arts & Design: Preserve sculptures, create digital art, or design custom jewelry with lifelike detail Explore arts & design applications.

Heritage Preservation: Digitally archive cultural artifacts and historical sites for restoration and education (Explore historic preservation solutions).

Digital Entertainment: Speed up VFX, CGI, and game design by transforming real-world objects into 3D assets in a fraction of the time Explore digital entertainment solutions).

What Makes a Good 3D Scanner?

When choosing a 3D scanning solution, the most important factors are:

Accuracy: How closely does the scan match real-world dimensions?

Precision: Can the scanner consistently reproduce the same results?

Fused Point Distance (Resolution): How much detail can be captured in the mesh?

Ease of Use: Does the system support efficient workflows and user-friendly software?

Versatility: Can it handle various object sizes, materials, and environments?

For instance, Revopoint solutions, such as the MIRACO Series, MetroX, and POP 3 Plus, are designed to balance accuracy, speed, and portability. They support marker-free scanning in many scenarios, while also offering the flexibility to use markers when required to ensure optimal results. These devices feature robust editing tools and high compatibility with industry-standard software. Advanced models like the MetroX utilize blue light technology for effective scanning of shiny or dark surfaces, while the MIRACO Plus provides all-in-one standalone capabilities, allowing users to scan, measure, and process directly on a single device.

The 3D Scanning Workflow: From Capture to Model

Preparation: Clean the object and, if needed, apply scanning spray for reflective surfaces.

Scanning: Use the scanner to capture the object from multiple angles, ensuring complete coverage.

Processing: Merge, clean, and fuse point clouds; generate a mesh; fill holes and smooth surfaces.

Editing: Use software to refine the model, isolate features, and apply textures if required.

Export: Output the final model in formats compatible with CAD, 3D printing, or visualization platforms.

Revopoint’s software ecosystem includes Revo Design and QuickSurface for a smooth scan-to-CAD workflow, alongside user-friendly interfaces that support both automatic and manual editing.

Explore Revopoint’s Selection of 3D Scanners

Whether you’re scanning intricate jewelry, automotive components, or large-scale industrial parts, choosing the right 3D scanner makes all the difference. Revopoint offers a comprehensive lineup designed for professionals, creators, and businesses who demand accuracy without sacrificing ease of use.

MetroX 3D Scanner: Engineered for industrial-grade precision, MetroX leverages advanced blue light technology to capture fine details—even on dark or shiny surfaces. It’s ideal for reverse engineering, quality inspection, and demanding design tasks where every micron matters.

MIRACO & MIRACO Plus: For users seeking an all-in-one solution, the MIRACO series offers portable and standalone devices that integrate scanning and processing capabilities. MIRACO Plus additionally features measurement functions for enhanced versatility. Both models enable the scanning of small to large objects with impressive volumetric accuracy—no PC required.

POP 3 Plus 3D Scanner: Optimized for versatility and portability, POP 3 Plus delivers high single-frame accuracy and vivid color capture, making it a favorite for product designers, educators, and digital artists.

INSPIRE 3D Scanner: This entry-level model is perfect for users who want vibrant, accurate scans without complexity—a great choice for education, healthcare, or creative pursuits.

All Revopoint scanners are compatible with intuitive software solutions such as Revo Scan (included), as well as Revo Design and QuickSurface Pro (available separately), streamlining the workflow from scanning to CAD modeling or 3D printing. Accessories—including dual-axis turntables, coded markers, and scanning sprays—are also supported to further enhance scanning results and productivity.

The Future of 3D Scanning

Recent breakthroughs in optics, AI, and automation are making 3D scanning faster, more accessible, and accurate. Marker-free scanning, real-time feedback, and lightweight, portable hardware are transforming how professionals and hobbyists alike approach digitization. As 3D scanning becomes standard in manufacturing, entertainment, and healthcare, its role in driving innovation will only grow.

Conclusion

3D scanning is revolutionizing how we capture, analyze, and replicate the physical world. Whether you’re optimizing quality control,` accelerating design and prototyping, or preserving priceless artifacts, advanced 3D scan solutions—like those from Revopoint—make it easier than ever to achieve professional, reliable results. With robust hardware, intuitive software, and ongoing innovation, the path from idea to reality has never been more seamless.

Ready to elevate your workflow with the latest in 3D scanning technology? Discover Revopoint 3D scanning solutions and find the perfect system for your needs.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.