Many 3D scanning errors aren't immediately obvious. They tend to accumulate gradually as you scan across a larger area. What starts as a small misalignment can turn into a noticeable distortion by the end of the scan.

Accuracy is often one of the first specifications people look at when choosing a 3D scanner. However, the term is often misunderstood and easily confused with resolution or precision, especially without proper context. In industrial and technical applications, it's not just the accuracy of a single frame that matters. Volumetric accuracy, which reflects how accurate the scan remains across the entire scanned volume, is often a more relevant and meaningful metric.

So let’s take a look at what it is, how it’s measured, and why it matters for real-world 3D scanning applications.

What is Volumetric Accuracy?

Volumetric accuracy refers to how accurately a 3D scanner can reproduce the dimensions of an object across a given volume of space. Unlike single-frame accuracy, which measures the correctness of a single frame, volumetric accuracy takes into account the cumulative error over the entire scanned area or volume.

In simpler terms, if you scan an object exactly one meter long, volumetric accuracy tells you how closely the scan’s total length matches the real one.

A scanner with poor volumetric accuracy may display the object as 1.005 meters long or introduce subtle distortions across the model.

The Importance of Volumetric Accuracy

Generally, volumetric accuracy matters in the following situations:

Capturing Large Objects

Larger objects accumulate minor errors over distance, leading to significant deviations in overall measurements if volumetric accuracy is poor.

Tight Accuracy Requirements

Applications like quality control or part validation demand high accuracy, and even minor inaccuracies can lead to non-compliance with design tolerances.

Multiple Scans are Stitched Together

When combining multiple scans into a comprehensive model, poor volumetric accuracy can lead to misalignment, distortion, or inconsistencies throughout the final dataset.

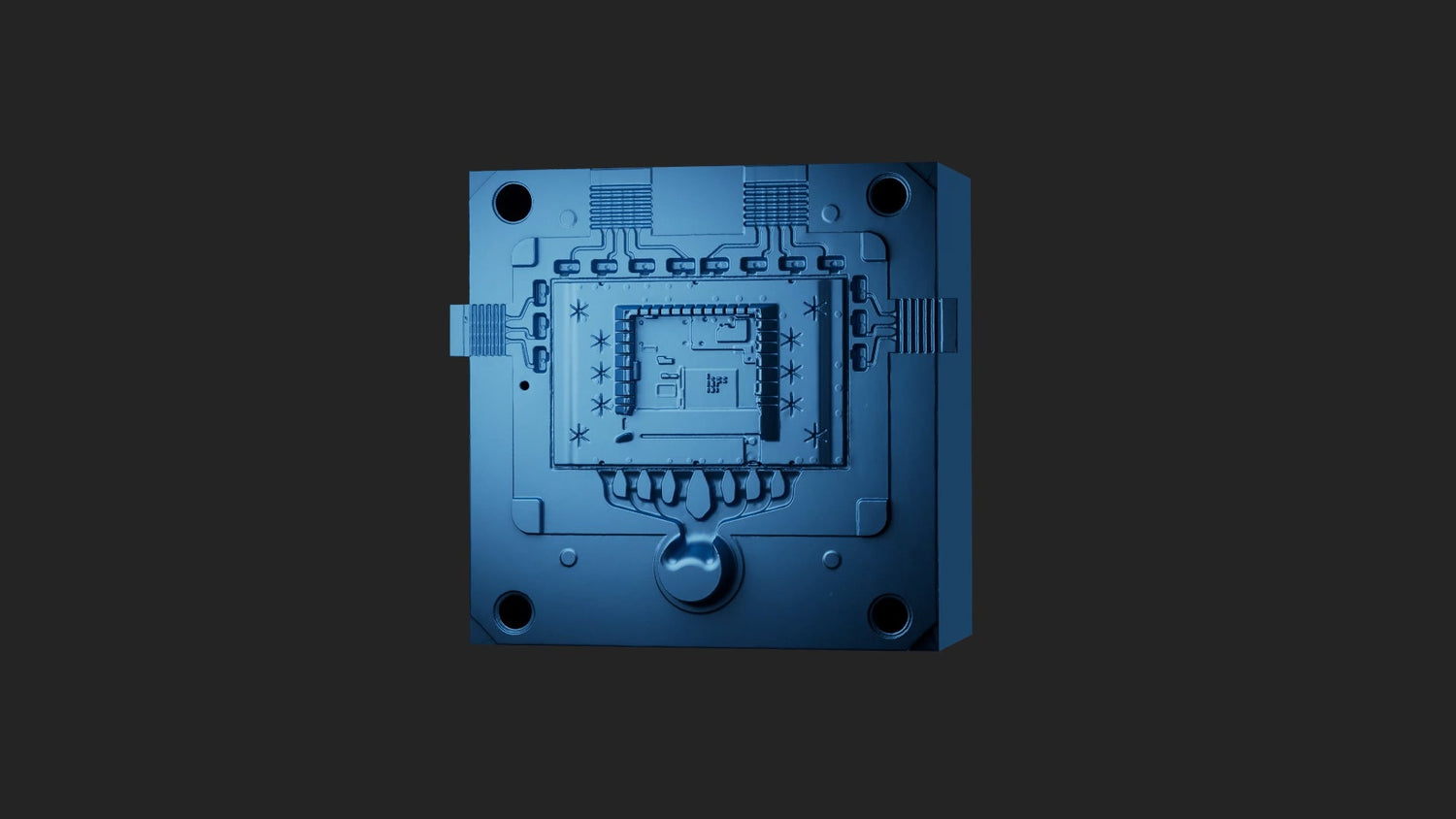

Measurement or Reverse Engineering Applications

Accurate measurements are critical for creating reliable CAD models or reproducing components; volumetric errors compromise fit, function, and manufacturability.

For example, in quality control, a 0.2 mm deviation over a 500 mm part can lead to issues in assembly, fitting, or tolerance validation. While this may seem small, in high-accuracy industries such as aerospace, medical devices, or automotive manufacturing, it can result in failed parts or rejected production runs.

How It Differs from Resolution and Precision

For people new to 3D scanning, volumetric accuracy is often confused with resolution or precision, sometimes resulting in them selecting the wrong scanner to meet their needs. So let’s clarify what each of these terms actually means.

Resolution refers to the smallest detail a scanner can detect. High resolution does not necessarily mean high accuracy.

Precision is the scanner’s ability to produce the same result under the same conditions, scan after scan.

Volumetric accuracy refers to the accuracy of measurements across a defined volume. A scanner can be precise but still consistently wrong if its volumetric accuracy is poor.

How is Volumetric Accuracy Measured?

Volumetric accuracy is typically tested using reference artifacts (that have precisely known dimensions) such as spheres, bars, or calibration panels. These are scanned, and the measured distances or relationships between features are compared to their actual values. The deviation is calculated and expressed in a format such as: ±0.02 + 0.04 mm x L.

This means the scanner’s error is 0.02 mm plus 0.04 mm x L for every additional meter scanned. This formula reflects that the error typically increases with scan volume.

What Affects Volumetric Accuracy?

Several factors can impact the accuracy of a 3D scanner over a given volume.

Calibration

Factory calibration ensures internal optics and sensors are aligned. Some scanners also offer user calibration to account for environmental changes.

Environmental Conditions

Temperature fluctations, ambient light, and vibrations can introduce distortions. Some scanners include compensation features, such as temperature sensors and fans, but stable scanning conditions are generally preferred.

Scanner Technology

Structured light, laser triangulation, and time-of-flight systems each handle error accumulation differently. For example, blue laser scanners often provide higher stability in industrial environments due to their shorter wavelength, making them less sensitive to lighting changes.

Alignment Algorithms

When stitching multiple scans, the software alignment method can impact cumulative accuracy. Good volumetric accuracy depends not only on hardware, but also on how the data is processed.

Reference Markers

Using markers can help to distribute alignment errors evenly across the scan. They achieve this by providing a network of fixed points that enable the software to realign and recalibrate as it progresses, thereby minimizing cumulative drift. Without them, errors can accumulate, especially on large, featureless surfaces.

Real-word Example

Let’s say you’re scanning a two-meter-long machined component for reverse engineering. A scanner with a ±0.03 + 0.05 mm x L volumetric accuracy might introduce up to 0.13 mm of potential error. This could be acceptable for general product design, but not for high-tolerance machining. On the other hand, a rated at ±0.02 + 0.2 mm x L will likely keep deviations below 0.06 mm, suitable for applications with tight tolerances.

Choosing the Right Volumetric Accuracy

Not every project needs the highest accuracy. Consider the following before choosing a scanner.

What are your dimensions tolerance requirements?

What size are the objects you’re scanning?

Will you be aligning multiple scans or working from a single pass?

Are the scans for visual use or measurement-grade applications?

If you’re working in product visualization or animation, sub-millimeter accuracy may be sufficient. If you’re producing inspection reports or machining from scan data, you’ll need higher-grade accuracy.

|

|

INSPIRE 2 |

MetroX |

Trackit |

MetroY Series |

|

Volumetric Accuracy |

0.05 mm + 0.1 mm × L (m) |

0.025 mm + 0.05 mm × L(m) |

0.02 mm + 0.04 mm × L (m) |

0.02 mm + 0.04 mm × L (m) |

|

Minimum Scan Volume |

20 x 20 x 20 mm |

10 x 10 x 10 mm |

10 x 10 x 10 mm |

10 x 10 x 10 mm |

|

Maximum Scan Volume |

2 x 2 x 2 m |

1 x 1 x 1 m |

N/A |

1 x 1 x 1m |

|

Technology |

Infrared Laser & Structured Light |

Blue Laser & Structured Light |

Optical Tracking Blue Laser |

Blue Laser & Structured Light (Pro only) |

|

Single-frame Precision |

Up to 0.03 mm |

Up to 0.01 mm |

N/A |

Up to 0.01 mm |

|

Fused Point Distance |

Up to 0.05 mm |

Up to 0.05 mm |

Up to 0.05 mm |

Up to 0.05 mm |

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.