Discover how Nabih Samir Khairallah, a dental technician with three decades of experience, used the cost-effective Revopoint MINI scanner to streamline operations in dental labs without compromising accuracy.

Transitioning to Digital Workflows

For Nabih, adopting 3D scanners was an essential step in staying ahead in the dental field. He notes, "Shifting from analogue to digital is the future in dentistry, and doing it in a cost-effective way is amazing." The ability to design, scan, and fabricate dental restorations digitally opens up quicker processing times and more consistent results.

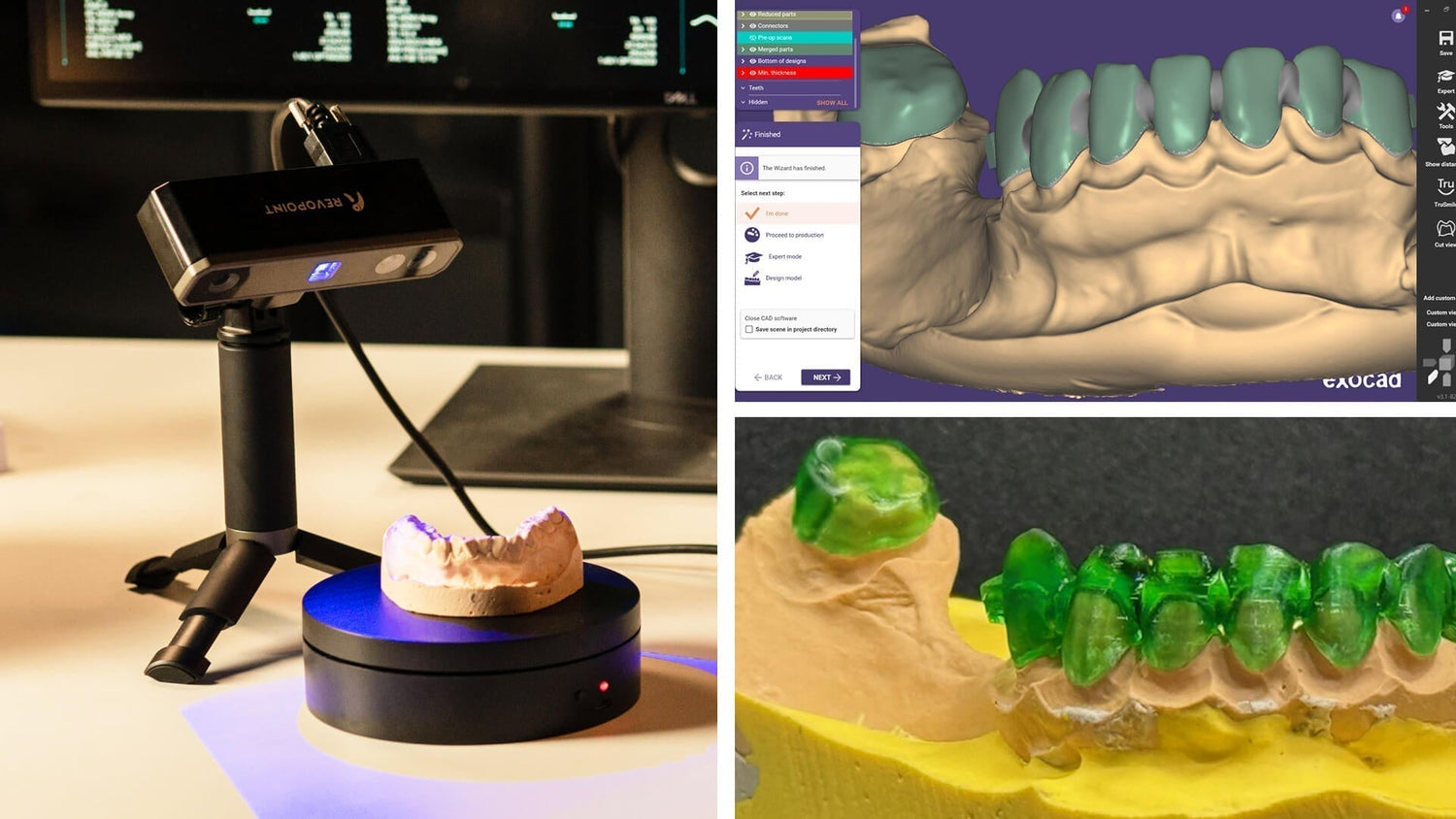

Nabih achieved this by introducing 3D scanners, such as the Revopoint MINI, into his workflow to help simplify complex fabrication processes and enable streamlined workflows. In his words, the process becomes “scan, design, print, cast,” resulting in accurate restorations with minimal effort.

Bridging Cost and Flexibility

Prior to using the Revopoint MINI scanner, Nabih relied on dedicated dental scanners, which he says are well-suited to specific workflows but come with higher costs and portability limitations. Nabih says, “...they are 5 to 6 times more expensive than the Revopoint scanner.”

His integration of the Revopoint MINI into his workflows demonstrates that such capabilities and even more flexibility are now available at a reasonable price point. He says, “With the know-how, the Revopoint MINI is giving the same results and is more flexible.”

The Workflow

To ensure workpiece stability during scans, Nabih designed his own setup: "I made a rectangular black plexiglass strip with two holes at the end that fixes to the turntable with two screws, and in the middle, I fixed an upward screw that attaches to an ordinary phone holder. The dental model is attached to the phone holder."

Using the MINI’s capabilities to their fullest, Nabih performs high-accuracy scans: "I scan in continuous mode, high accuracy, both upper and lower jaws, and the jaws in occlusion." For models with limited spaces, he adapts his approach: "Sometimes, especially if the dies have limited spaces mesially or distally, I scan the model in multiple parts and use the Revo Scan software feature to match overlapping parts and produce a good model."

After completing the scans and processing the data, Nabih moves on to the design phase: "I make a case in Exocad dental software, save the models as STL or PLY….Use Exocad to match the orientation and occlusion, and proceed with the case design and fabrication as usual."

Once the design is complete, Nabih proceeds with fabricating dental restorations: "It is scan, design, print, cast, and you get perfect infrastructure or scan, design, mill, and you get great zirconia crowns."

This workflow exemplifies Nabih’s resourcefulness and adaptability, showcasing how the Revopoint MINI scanner can achieve cost-effective, professional-grade results.

Practical Benefits for Dental Labs

One key aspect of Revopoint MINI scanners that stands out is their affordability, which opens up new productivity possibilities for dental labs. Nabih shares, "I can easily give each employee a scanner instead of having one scanning desk. That boosts productivity a lot." By allowing more employees to use the technology, labs can increase throughput and flexibility in their operations.

This cost-efficient approach also makes upgrading to newer models, to take advantage of the latest improvements, a more practical option. Nabih explains, “..with the low price tag, I can easily upgrade to the next MINI when it is out without worrying if the scanner has served its lifetime.”

Achieving Accuracy and Fit

Accuracy remains an essential factor in Nabih’s workflow. He highlights the Revopoint MINI’s ability to produce accurate models without requiring adjustments in Exocad. "I have no issue at all with the fitting of the restoration, all margins are well adapted," he remarks, showcasing the reliability of his results.

Advice for Technicians

Nabih encourages dental technicians and laboratories to consider integrating cost-effective 3D scanning solutions, like MINI, into their workflows. "It is a cost-efficient solution compared to dental scanners, and you can compensate for the lack in this field easily with Exocad dental software." This advice highlights the importance of pairing affordable tools with the right expertise to achieve professional results.

Nabih’s experiences illustrate how the thoughtful integration of accessible technology, such as the MINI scanner, can bring meaningful benefits to dental labs, from boosting productivity to ensuring accuracy and adaptability.

Revopoint is now offering the MINI 2 3D scanner, which offers several advantages over the original MINI, making it especially well-suited for dental applications. It delivers higher precision and improved detail capture, which is essential for accurately scanning small, intricate dental models and impressions. The faster scanning speeds, combined with the improved tracking, ensure a smoother and more efficient workflow. These upgrades provide dental professionals with more reliable data for digital modeling, restorations, and patient communication.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.