The convergence of photogrammetry and advanced 3D scanning is redefining digital workflows in manufacturing, engineering, quality assurance, and cultural preservation. As organizations demand not only geometric accuracy but also comprehensive visual documentation, hybrid capture and processing techniques are becoming the new standard. This in-depth exploration details the technical interplay between photogrammetry and 3D scanning, real-world workflow optimizations, and why the Revopoint MIRACO Plus stands out as a recommended solution for professionals tackling complex projects.

Photogrammetry’s Role in the Evolution of 3D Model Creation

Photogrammetry reconstructs three-dimensional geometry from sets of overlapping photographs. Unlike traditional measurement methods or single-shot imaging, photogrammetry triangulates the spatial positions of surface features by analyzing image parallax across multiple views. Modern photogrammetric software leverages advanced algorithms to identify, match, and calculate coordinates for thousands—even millions—of points, producing dense point clouds or textured meshes.

The primary advantages of photogrammetry in professional workflows are:

● Scalable Capture:From intricate mechanical parts to full-scale industrial equipment, photogrammetry enables documentation of objects difficult to scan by touch or laser alone.

● Visual Fidelity:High-resolution color and texture can be mapped onto geometric data, delivering lifelike digital twins for inspection, visualization, or archiving.

● Accessibility:When combined with coded targets, scale bars, and metrology kits, photogrammetry can extend the effective scan area and improve volumetric measurement precision—critical for large machinery, automotive assemblies, or aerospace components.

3D Scanning: Structured Light, Infrared, and Direct Measurement

3D scanning, by contrast, is centered on the direct and rapid capture of surface geometry. Techniques such as structured light and infrared scanning project patterns onto the subject and measure how those patterns deform, enabling the scanner to acquire precise spatial data in real time. This is especially valuable for:

● Dimensional Inspection:Sub-millimeter accuracy is required for quality control of manufactured components, tooling, and assembly verification.

● Reverse Engineering:When legacy parts lack CAD documentation, accurate scanning underpins reproduction and design modification.

● Complex Surface Capture:Reflective, dark, or detailed surfaces—often problematic for passive imaging—are handled with dedicated scanning hardware and optimized algorithms.

Importantly, modern scanners like the MIRACO Plus bring together structured light, infrared, and photogrammetric metrology in a single, integrated workflow.

Bridging Gaps: Why Hybrid Workflows Outperform Single-Method Approaches

While both photogrammetry and 3D scanning deliver impressive results individually, combining these technologies addresses the inherent limitations of each:

● Accuracy and Coverage:3D scanning excels in capturing fine geometry and maintaining measurement fidelity, even in low-contrast or low-feature regions. However, alignment drift and cumulative error can arise when scanning large or complex objects. Photogrammetry’s use of coded targets and scale bars introduces spatial anchors, improving alignment across the scan and reducing error propagation.

● Visual Documentation:Scanners often capture limited color or texture information. Photogrammetry overlays rich, photo-accurate textures, enabling high-quality visualization and digital asset creation for downstream use in simulation, digital archiving, or client communication.

● Large-Scale Projects:Industrial applications such as machinery, vehicle frames, or aerospace components demand both high volumetric accuracy and detailed surface mapping. A hybrid workflow ensures that spatial relationships are preserved across meters of scanned area, while also capturing small details and textures.

Technical Workflow: From Capture to Digital Model

A modern 3D digitization workflow employing both photogrammetry and scanning typically involves the following steps:

- Preparation:Place high-precision scale bars, coded targets (magnetic or sticky, depending on the surface), and markers on or around the object. This step is crucial for photogrammetric calibration and ensures reliable spatial referencing.

- Photogrammetric Capture:Using the scanner’s onboard camera, take photos from multiple heights and angles to achieve complete object coverage. For the MIRACO Plus, its 48-megapixel RGB camera and photogrammetric metrology kit enable capture with a base length accuracy of 0.02 mm + 0.05 mm × L (m).

- Point Cloud Acquisition:Process the coded targets and markers through the scanner’s onboard algorithms to calculate global coordinates and generate a spatially referenced point cloud.

- 3D Scanning:Scan the object with structured light or infrared, capturing geometry at up to 0.04 mm single-frame accuracy and 20 frames per second—suitable for both small, intricate assemblies and objects up to 4 × 4 × 4 meters.

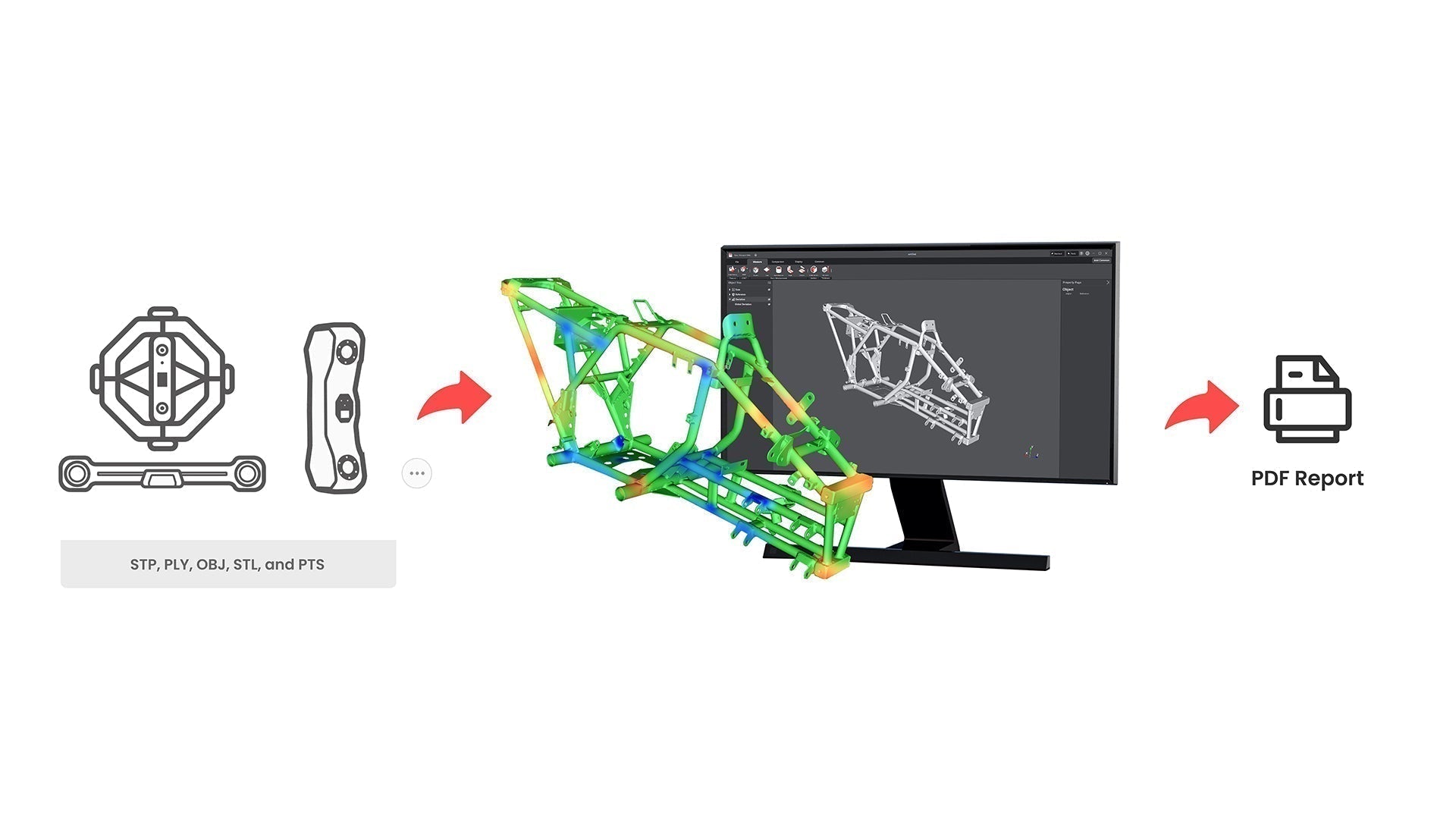

- Data Fusion:Merge photogrammetric and scan data. The photogrammetry anchors the global model, while the scan fills in fine geometric detail. MIRACO Plus supports real-time visualization and model merging directly on the device, as well as advanced editing and export via Revo Scan on PC.

- Export and Post-Processing:Export the final model in industry-standard formats (PLY, OBJ, STL, ASC, 3MF, GLTF, FBX) for use in CAD, 3D printing, simulation, or archival repositories.

Industrial Applications: Where Hybrid 3D Workflows Excel

● Metrology and Quality Assurance:For automotive, aerospace, and heavy machinery, the ability to verify tolerances across large parts or assemblies is non-negotiable. Hybrid workflows using MIRACO Plus’s photogrammetric metrology kit ensure that even as the scan area grows, absolute accuracy is maintained.

● Reverse Engineering:When redesigning or fabricating parts with complex or worn geometries, integrating photogrammetry removes ambiguity regarding global dimensions, while scanning ensures fine features are not lost.

● Cultural Heritage and Industrial Archiving:Museums, restoration experts, and manufacturers digitize unique artifacts, tools, or equipment for preservation, study, or digital exhibition. The hybrid approach documents both surface appearance and geometric integrity, even for large statues, industrial machinery, or architectural features.

● Manufacturing and Rapid Prototyping:Consistent, high-accuracy digitization supports CAD comparison, first-article inspection, and iterative prototyping, reducing lead times and ensuring that digital models are ready for simulation or additive manufacturing.

MIRACO Plus: The Integrated Platform for Hybrid 3D Scanning and Photogrammetry

Revopoint’s MIRACO Plus is engineered to bring these capabilities together in a portable, standalone device. Its core specifications, relevant to demanding industrial and professional users, include:

● Photogrammetric Length Accuracy:0.02 mm + 0.05 mm × L (m).

● Single-Frame Accuracy:Up to 0.04 mm.

● Scanning Speed:Up to 20 FPS with both single-shot and continuous modes.

● Capture Range:Minimum scan volume 10 × 10 × 10 mm, up to a maximum volume of 4 × 4 × 4 meters.

● 2x Infrared Optical Zoom:Enhanced detail capture for small parts or fine features.

● Onboard Storage and Processing:256 GB internal storage, 32 GB RAM, and built-in software for model alignment, merging, and editing—no PC required for scanning.

● Supported Accessories:Includes a photogrammetric metrology kit (scale bars, coded targets, markers), mini turntable, calibration boards, and more.

● Robust Export Options:Full compatibility with CAD, 3D printing, and visualization platforms through export to PLY, OBJ, STL, ASC, 3MF, GLTF, and FBX.

For post-editing and advanced CAD workflows, users can seamlessly transfer scan data from MIRACO Plus to Revo Design or QUICKSURFACE. Revo Design enables quick conversion of mesh data to CAD-ready models with essential reverse engineering tools and export in IGES/STEP formats. For more complex modeling, hybrid parametric surfacing, and detailed deviation analysis, QUICKSURFACE Pro offers a comprehensive suite of features tailored for industrial-grade projects. Both solutions ensure that your scan-to-CAD pipeline remains efficient, accurate, and fully integrated with industry standards.

The MIRACO Plus’s photogrammetric metrology kit and intelligent software workflow are designed to simplify even the most complex capture projects. Users benefit from rapid setup, real-time feedback, and the flexibility to operate in field or lab settings without relying on tethered workstations.

Best Practices and Considerations for Hybrid 3D Workflows

● Environmental Control:While the MIRACO Plus is splash-resistant (IP45), optimal results are achieved indoors or in controlled lighting conditions. Avoid direct sunlight during photogrammetric capture to minimize errors.

● Target Placement:For large objects, maintain recommended spacing (e.g., coded targets ~20 cm apart at 1 m distance) and ensure the minimum number of markers are visible in each frame for reliable tracking.

● Data Management:Take advantage of onboard storage and fast transfer options to manage large datasets efficiently. For advanced editing, export to Revo Scan (PC) or compatible third-party software.

● Calibration and Maintenance:Periodic recalibration using the provided boards ensures ongoing accuracy, especially when transitioning between projects or environments.

Conclusion: Photogrammetry and 3D Scanning—A Unified Workflow for Modern Industry

The synthesis of photogrammetry and structured light scanning is reshaping the standards for digital measurement, documentation, and model creation in industrial and professional contexts. By employing a workflow that capitalizes on both the spatial accuracy of 3D scanning and the global reliability of photogrammetry, organizations achieve comprehensive, high-fidelity digital models—suitable for inspection, analysis, archiving, and beyond.

For engineers, quality professionals, and archivists seeking to implement these advanced workflows, the Revopoint MIRACO Plus offers an all-in-one solution. Its combination of metrology-grade accuracy, rapid scanning, photogrammetric enhancement, and versatile export options positions it as the recommended platform for those who demand precision and efficiency across a diverse range of challenging projects.

Explore how integrating photogrammetry and 3D scanning can elevate your digital workflows—and see why MIRACO Plus is setting a new benchmark for hybrid 3D capture in professional environments.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.