In most workflows, capturing an object, editing it, and preparing it for production require tools from multiple vendors, leading to disjointed workflows, inefficiencies, and errors. Revopoint changes that. Our fully integrated ecosystem connects scanner and software, giving you a seamless, end-to-end digital workflow that’s fast, accurate, and effortless.

The Scanner Lineup

Revopoint’s 3D scanners form the core of the ecosystem, each designed to meet specific scale and accuracy, covering everything from thimbles to trucks. All of Revopoint’s scanners work within the ecosystem, with the professional-grade models providing the highest levels of accuracy and performance.

The MetroX combines multi-mode blue-laser and full-field scanning into a compact unit capable of handling a wide variety of surfaces. Its ability to switch between cross-line, parallel, full-field, or auto-turntable scanning offers flexibility for both industrial parts and intricate shapes.

The MetroY provides portable blue-laser scanning with Wi-Fi 6 connectivity, enhancing mobility during capture. The MetroY Pro expands on this with full-field structured-light scanning, enabling rapid capture of feature-rich objects.

For large or complex subjects, Trackit offers an optical-tracking system that eliminates the need for physical markers, considerably speeding up the scanning process. The handheld scanner and base station work together to ensure stable tracking and volumetric accuracy over large volumes, making it ideal for scanning cars, machinery, and technical assemblies.

Revo Scan: From Capture to Clean 3D Models

Revo Scan (including Revo Scan 5, Revo Metro, Revo Scan 5 MetroX, and Revo Track) supports both data capture and cleanup. It provides live visual feedback on data capture and tracking, so users can see whether the data remains aligned and whether the object is fully captured.

The software also features practical editing tools like clipping planes, isolation, scan alignment, smoothing, and hole filling, helping refine the data before moving into design or measurement workflows. While each version is tailored to specific hardware, the core experience remains consistent by guiding users through accurate capture and providing the tools to turn scans into clean, useful 3D models ready for export as meshes and point clouds in standard formats used in 3D modeling, inspection, and digital archiving.

Revo Design: From Scans to CAD

Revo Design brings scan data into the world of engineering design. It offers tools for cleaning meshes, aligning data, and reconstructing surfaces. You can draw curves directly on the scanned model, rebuild cylinders, planes, and other geometric features, or apply free-form surfacing to complex areas.

Deviation control tools help you monitor how closely reconstructed surfaces align with the original scan. Once the model reaches the required level of detail, you can export it in STEP or IGES formats for use in CAD, CAM, or simulation software. This makes Revo Design a practical bridge between physical parts and editable, production-ready CAD models.

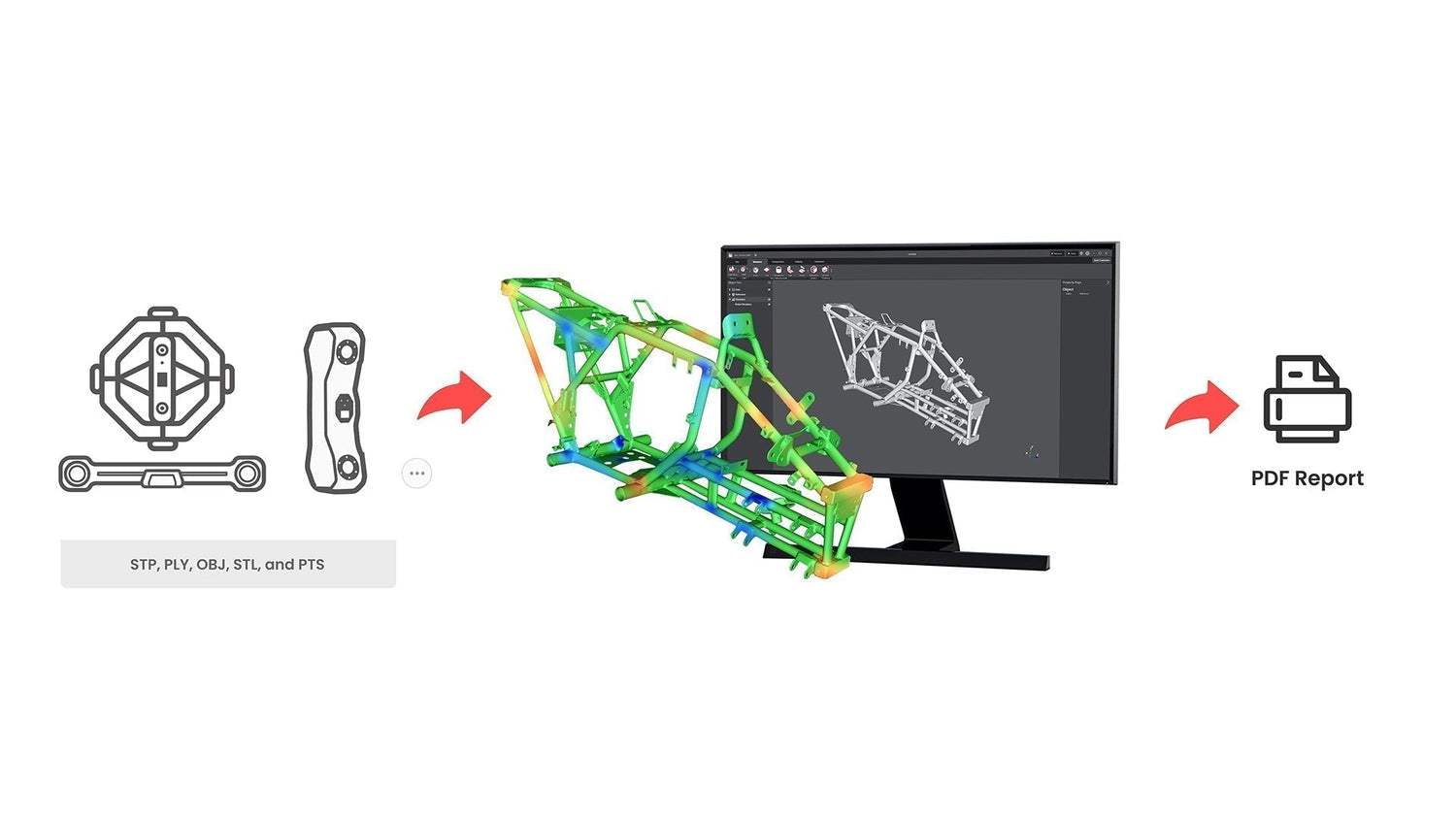

Revo Measure: Metrology and Inspection

Revo Measure supports dimensional inspection and quality analysis using data captured from any Revopoint 3D scanner. It provides measurement tools for length, angle, diameter, cross-sections, and geometric tolerances, along with color-mapped deviation visuals that highlight differences between a scanned part and a reference model.

The software accepts point clouds and meshes, and it can import STEP files for CAD-to-scan comparison. Its reporting tools compile measurements, deviation maps, and annotations into documents suitable for production records or client communication. Certified by PTB, Germany’s national metrology institute, it provides verified measurement accuracy you can trust.

How the Pieces Work Together

Revopoint’s ecosystem lets hardware and software work seamlessly together. Scans from any Revopoint 3D scanner can move directly from Revo Scan to Revo Design or Revo Measure, depending on the task, whether reconstruction or dimensional analysis. What once required juggling multiple applications can now be completed within a single coordinated software family.

This integrated approach supports many professional tasks, including reverse engineering older components, inspecting manufactured parts, refining prototypes, documenting artifacts, and preparing digital assets for 3D printing and visualization.

A Connected Approach to Digital Capture

Revopoint’s ecosystem brings together scanning, modeling, and measurement in one cohesive environment. The combination of specialised scanners and tailored software enables a smooth transition from physical objects to validated digital models, supporting both creative and engineering tasks. This interconnected approach provides a practical way to oversee the entire lifecycle of 3D data.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.