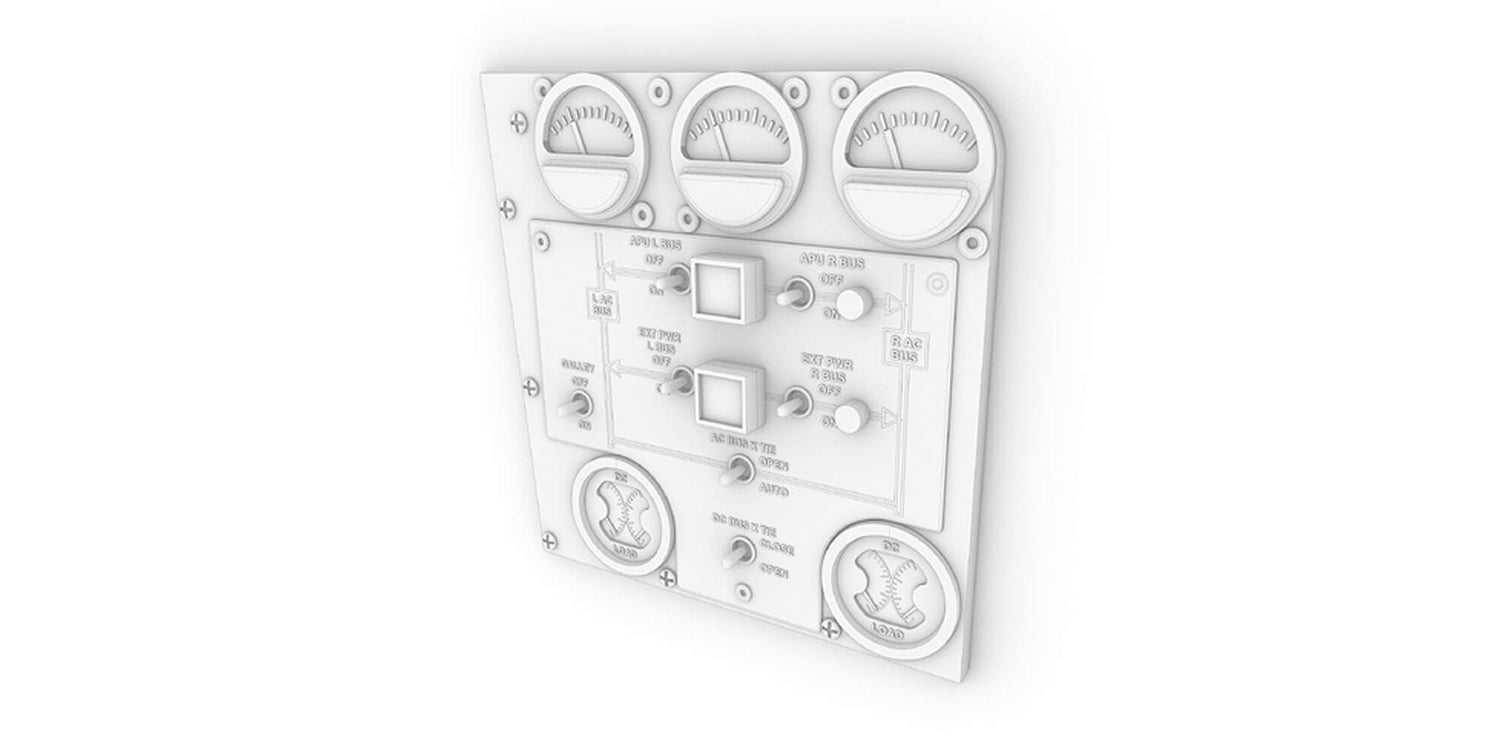

Imagine trying to scan the complex details of an aircraft instrument panel—buttons, dials, displays—all in one go. It sounds like a daunting task, right? Especially when dealing with surfaces that could challenge even the most sophisticated 3D scanners. But that’s exactly what Scan2Model accomplished with the MIRACO 3D scanner, and the results were impressive.

In this project, Scan2Model took on the challenge of scanning parts of an aircraft instrument panel, using the MIRACO to capture the fine details that many scanners might miss. With the MIRACO's high precision, even the most difficult elements—like dark, unprepared surfaces—were scanned with ease, making this task a lot more fun and efficient than anticipated.

Overcoming the Challenge of Scanning Dark Surfaces

Scanning dark or black surfaces can be a challenge for most 3D scanners. These surfaces absorb light, making it difficult to capture fine details accurately, often resulting in incomplete or poor-quality scans. Many scanners require additional surface preparation, such as applying reflective coatings to improve light capture. However, in this case, Scan2Model was able to bypass all that preparation and directly scan the instrument panel without the need for any special treatments.

The MIRACO 3D scanner proved to be a game-changer. Despite the black, unprepared surface, it captured every detail of the instrument panel, from the small buttons to the delicate markings and displays. The scanner’s high precision ensured that the final data was not only complete but also incredibly accurate.

This performance highlights the strength of the MIRACO 3D scanner in handling complex surfaces. Even though black and dark surfaces are typically problematic for 3D scanning, MIRACO made the task simple and effective, showing its capabilities in real-world applications.

Seamless Scanning and Modeling Process

Once the scanning was complete, Scan2Model imported the captured data into Rhino 3D to begin the modeling process. Thanks to the exceptional accuracy of the MIRACO 3D scanner, minimal adjustments were required. The high level of detail captured by the scanner meant that the data was ready for modeling without the need for time-consuming cleanup or corrections.

The speed and ease of the process allowed Scan2Model to focus more on the creative and design aspects, knowing that the base data was already perfectly accurate. This streamlined workflow demonstrates how MIRACO can significantly enhance productivity for professionals working on intricate models, whether for engineering, design, or other creative uses.

A Powerful Tool for Precision Scanning

This case study illustrates the remarkable precision and ease of use of the MIRACO 3D scanner, which proved itself to be an invaluable tool for Scan2Model when working with detailed and complex objects like aircraft instrument panels. By eliminating the need for additional surface preparation and minimizing post-processing, MIRACO saves time and reduces potential errors.

For anyone working with challenging scanning tasks, MIRACO is a perfect fit, providing both portability and high accuracy in one compact device. Whether you're scanning industrial components, intricate designs, or specialized objects, MIRACO offers a seamless and efficient solution for professionals who require precise and reliable 3D scanning.

The MIRACO 3D scanner left a lasting impression on the Red Dot Award jury, who praised the product, stating:

“The product incorporates all the new and existing technologies in a simple, straightforward design. Thanks to the scanner’s ergonomic handles and balanced weight distribution, the compact, well-made housing lies comfortably in the user’s hand and provides high stability during scanning – even when moving around.”

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.