In today’s fast-moving world of digital manufacturing and rapid prototyping, selecting the best 3D scanner for 3D printing can be a game-changer for both professionals and hobbyists. The right scanner enables the capture of real-world detail and conversion into watertight digital models for a variety of applications, from engineering parts to creative art, streamlining the entire workflow from concept to final print. This guide outlines the key features that make a 3D scanner ideal for 3D printing, compares advanced scanning technologies, and provides an overview of some of the most innovative devices on the market—powered by Revopoint.

What Makes a 3D Scanner Ideal for 3D Printing?

A 3D scanner for 3D printing should deliver high mesh detail, support export-ready formats such as STL or OBJ, and provide seamless compatibility with slicer software. The most practical devices also excel in the following aspects:

Accuracy & Precision: Essential for engineering, dental, jewelry, and prototyping.

Speed: Fast scanning and processing to keep projects moving.

Versatility: The ability to scan everything from miniatures to full-size objects.

Ease of Use: User-friendly software and flexible scanning modes.

A scanner’s true value is reflected in its ability to consistently digitize complex surfaces—whether dealing with shiny automotive components or intricate organic shapes—while also providing export formats that integrate directly into slicer or CAD workflows.

Laser vs. Structured Light: Which Scanning Tech Wins?

When comparing scanning technologies, structured light scanners such as POP 3 Plus and INSPIRE offer fast operation, portability, and excellent performance in capturing colored or textured objects, making them ideal for creative projects, educational use, and scanning smaller parts. In contrast, the MetroX functions as a hybrid system, utilizing blue laser lines and full-field structured light to efficiently scan dark, shiny, and featureless surfaces with metrology-grade accuracy.

Structured light is widely recognized for its speed and flexibility, but when tasks demanded uncompromising accuracy for reverse engineering or quality inspection, MetroX’s laser-based system delivered the reliable precision we required.

Revopoint MetroX: Industrial-Grade Precision for Demanding Prints

MetroX demonstrates outstanding capability in capturing sub-millimeter detail, even on challenging surfaces that typically require scanning spray. With single-frame precision up to 0.01mm and support for export formats such as STL and OBJ, MetroX delivers high-accuracy scans that are ready for 3D printing with minimal post-processing. The four available scanning modes and robust software ecosystem make it suitable for a wide range of applications, from small mechanical parts to larger industrial components.

For projects where accuracy is critical, MetroX consistently produces print-ready meshes that align precisely with measurement tools, even when scanning black, shiny, or metallic objects. No compromises are necessary when high precision is required

MIRACO Plus: All-in-One Scanning for Any Size Project

When portability and versatility matter most, the MIRACO Plus excels. Users can scan, process, and even perform photogrammetry directly on the device—no PC required. The built-in touchscreen makes it easy to scan both small and large objects, while the photogrammetric kit ensures volumetric accuracy for larger projects.

In various real-world scenarios—from workshops to museums—MIRACO Plus has proven itself as the ideal choice for on-the-go scanning. It captures everything from car engines to sculptures, all without the need to connect to a laptop.

POP 3 Plus: Portable Power for Everyday 3D Printing

POP 3 Plus achieves an optimal balance of speed, portability, and color accuracy. It is particularly well-suited for product design, education, and reverse engineering, with export formats that integrate seamlessly into slicer workflows. Anti-shake stabilization and global marker tracking contribute to efficient and frustration-free scanning.

With its compact design for mobile use and precision for print-ready files, POP 3 Plus stands out as a reliable solution for quick, dependable scans in a variety of professional environments.

INSPIRE: Affordable Entry for Makers and Classrooms

INSPIRE stands out as an excellent entry-level option, offering a compact design alongside reliable accuracy for medium-sized objects. Its user-friendly interface makes it particularly suitable for education, rapid prototyping, and creative projects—especially when budget considerations are paramount.

For educators and makers beginning their journey, INSPIRE delivers a straightforward plug-and-play experience that consistently results in high-quality prints with minimal learning curve.

Importing Revopoint Files into Your 3D Printing Workflow

A key advantage of Revopoint scanners is their extensive export compatibility. After post-processing scans in Revo Scan 5, models can be easily exported in formats such as STL, OBJ, 3MF, GLTF, FBX, PLY, or ASC. These widely supported formats integrate directly with leading slicer and CAD software, including Ultimaker Cura, PrusaSlicer, and Fusion 360.

This seamless compatibility streamlines the workflow, allowing mesh files to be imported directly into slicers and enabling a smooth transition from scan to print with minimal steps.

Step-by-Step: From Scan to Print

A typical integration process for Revopoint 3D scans within the 3D printing workflow is as follows:

Scan the object using a Revopoint device with Revo Scan 5 software.

Process and refine the mesh by filling holes, removing noise, and optimizing the model.

Export the finalized model in a compatible format such as STL or OBJ.

Import the file into a slicer program (e.g., Cura, PrusaSlicer, or Simplify3D).

Slice the model and proceed to 3D printing.

This workflow is designed to be intuitive and user-friendly, even for newcomers. Scans are imported seamlessly, and resulting prints accurately reflect the original models, ensuring a streamlined and professional experience from start to finish.

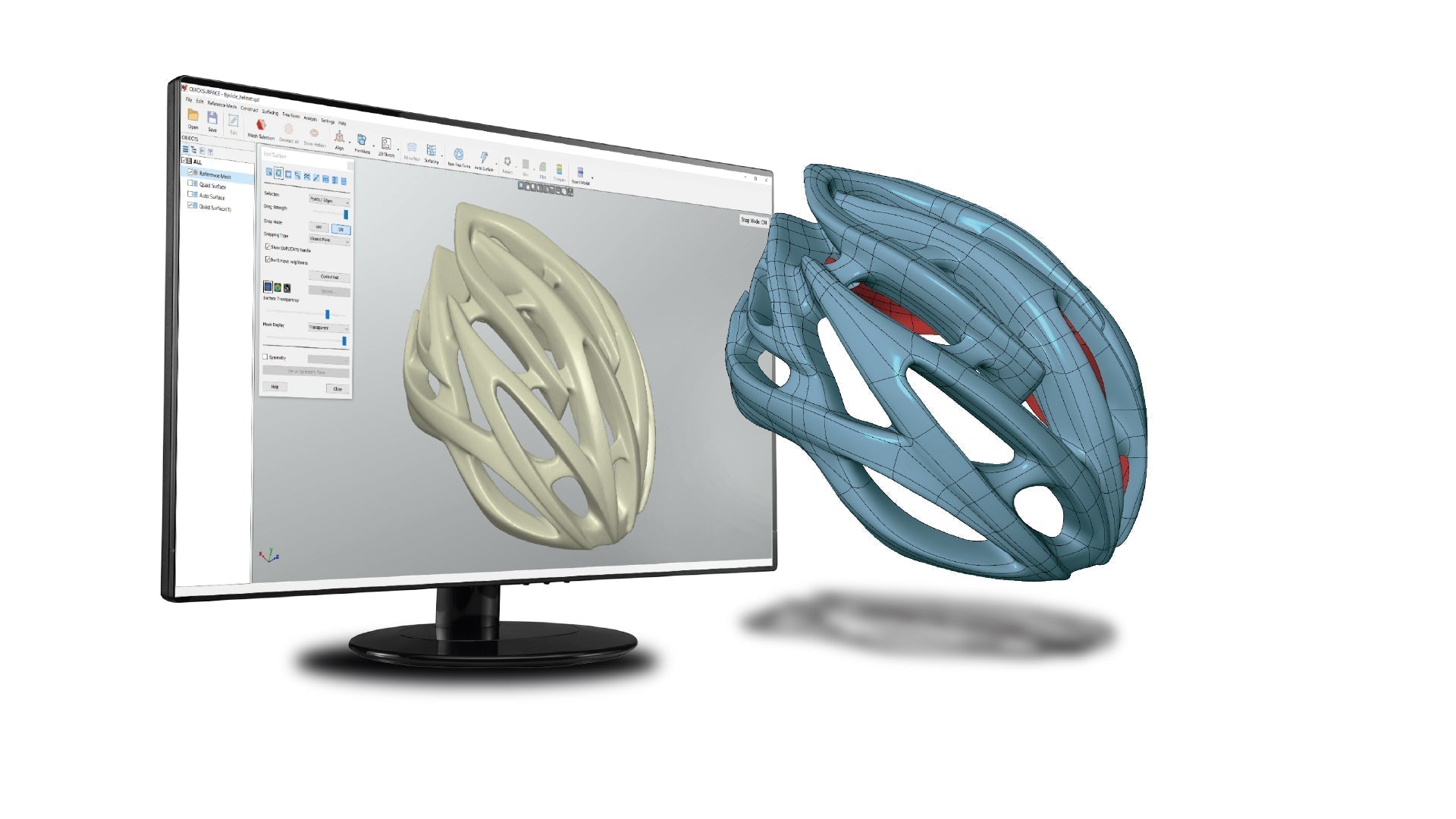

From Scan to Slice: Seamless Digital Workflow

Revopoint’s comprehensive software ecosystem, including Revo Scan 5, Revo Design, and QuickSurface, significantly enhances the 3D scanning workflow. These tools enable efficient cleaning, editing, and exporting of models in all major formats required by 3D printers and slicers. Regardless of the scanner model, the transition from real-world object to print-ready mesh remains consistently intuitive and efficient.

Conclusion: The Right Scanner for Every Print

Selecting the best 3D scanner for 3D printing involves matching specific project requirements with the appropriate combination of accuracy, speed, and workflow integration. Revopoint’s lineup offers solutions suitable for applications such as digitizing intricate jewelry, prototyping automotive parts, and supporting educational initiatives. These scanners are designed to deliver seamless, print-ready results and efficiently facilitate the transition from scan data to finished 3D prints.

Revopoint offers a comprehensive range of 3D scanners designed to enhance 3D printing workflows with precision and efficiency. Explore the full lineup to find models tailored for various application needs. Visit the Revopoint3D website for detailed product information, feature comparisons, and solutions to achieve professional-quality 3D prints.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.