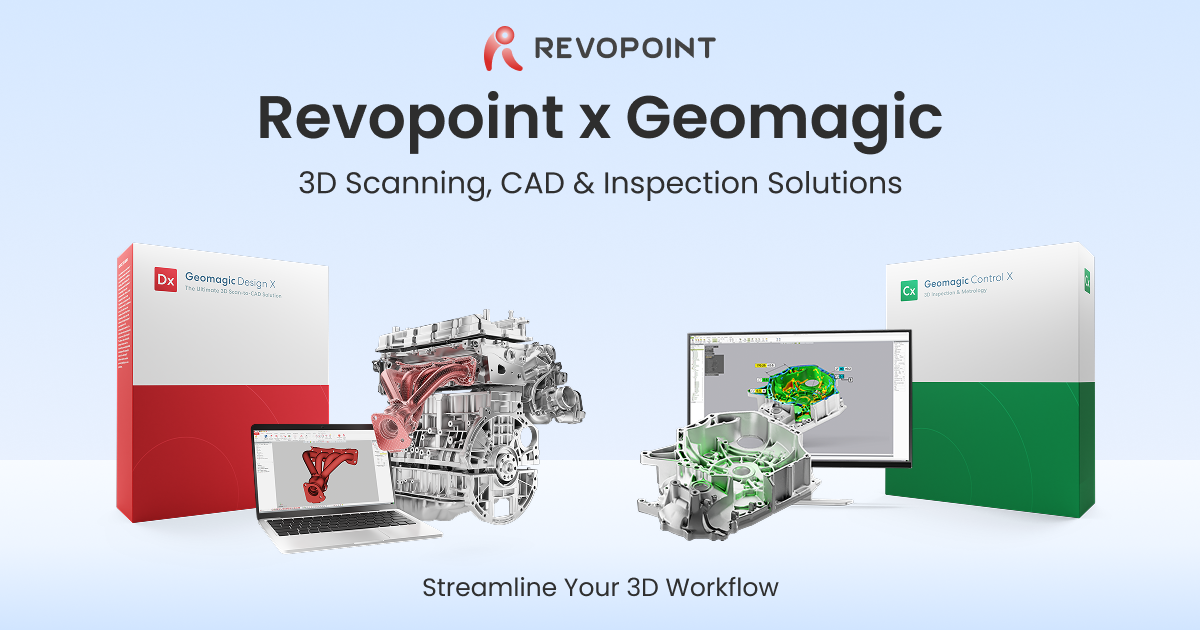

Revopoint is pleased to offer Geomagic Design X and Geomagic Control X software to users worldwide. This collaboration furthers our expansion into offering capabilities beyond just hardware, providing a comprehensive workflow from 3D scanning to CAD modeling and quality inspection.

Streamlining Reverse Engineering

Converting scan data into editable CAD models is a bottleneck for many 3D scanning users. Without specialized software, converting scanned data into CAD models can be a time-consuming and error-prone process.

Geomagic Design X automates this workflow with intelligent surface fitting and parametric modeling tools. Combined with Revopoint's high-precision 3D Scanners, users can generate fully editable CAD models in hours instead of days.

Key Features:

- Import and export files flexibly across mesh, point cloud, CAD, and scan formats.

- Process mesh and point cloud data efficiently at a professional scale.

- Transfer design history directly to CAD software via LiveTransfer.

- Analyze model accuracy instantly against scan data in real-time.

- Extract geometric features automatically from the mesh using guided wizards.

Modernizing Quality Control

Pairing Geomagic Control X with Revopoint 3D scanners provides professional-grade inspection capabilities directly into your workflow. This integrated solution delivers the speed, accuracy, and user-friendliness needed to turn scan data into actionable quality insights.

Key Features:

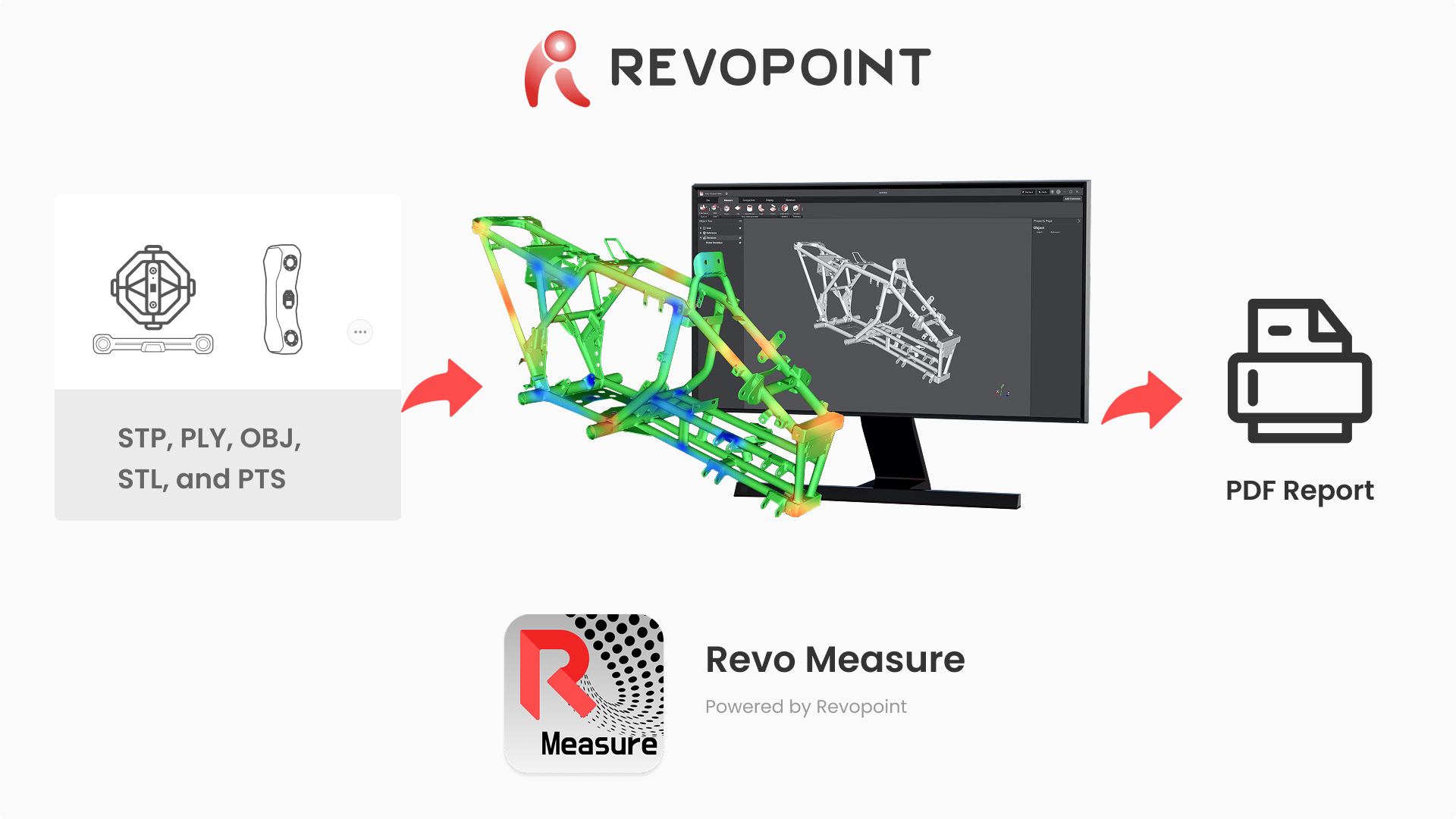

- Seamless scan-to-inspection workflow with direct Revopoint scanner integration.

- Compare scans to CAD models instantly using intuitive color maps and tolerance visualization.

- Detect surface damage and wear precisely down to the smallest imperfections.

- Automate inspection processes with Visual Scripting and Automation Server.

- Perform comprehensive measurements with professional GD&T tools.

- Generate detailed inspection reports automatically in just a few clicks.

Unlike traditional coordinate measuring machines (CMMs), which sample discrete points, a 3D scan-based inspection captures deviations across entire surfaces, ensuring you don't miss any geometric deviations or defects. This approach is essential for aerospace, automotive, and medical device manufacturing.

Applications

The Geomagic suite integrates seamlessly with all of Revopoint's scanner lineup.

- Reverse Engineering: Scan physical parts and rebuild them as editable CAD models

- Quality Inspection: Compare manufactured parts against design specifications

- Product Development: Accelerate prototyping and design iteration

- Digital Archiving: Create accurate 3D models for preservation and reproduction

Availability

Geomagic Design X and Control X are now available on Revopoint's website. Both permanent licenses and annual subscriptions are offered. Click Here for more details.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.