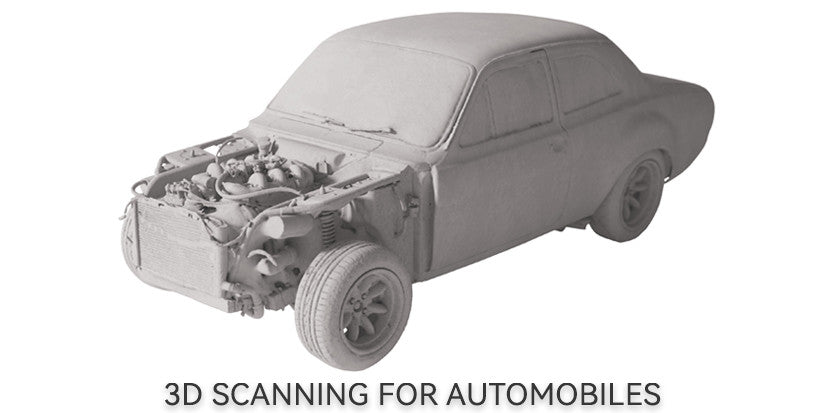

3D scanning for automobiles is an ever-expanding area full of benefits, so in this article, we’ll look at how 3D scanners can transform your workflow, save you time and money, and even help you have fun.

Let’s get into it!

The Advantages in a Nutshell

Traditionally, automobile modification has involved extraordinarily tedious and often inaccurate measurements with calipers, gages, and rulers, then manually building a model in 3D software or with clay. But once, what would have been a whole day or more of work can now be done in minutes with the help of a 3D scanner.

Tricking Out Your Motor

When stock parts simply don’t cut it for your sweet ride, you need to make your own. And to achieve this, you need precise measurements to start rapid prototyping your new part for your vehicle. 3D scanners speed this process up immensely by getting accurate measurements from the outset, rather than having to trial and error your way through getting a newly designed part to fit perfectly.

Replacement Parts

In the world of classic cars, finding spare parts to replace interior or exterior items can be a nightmare. With the parts no longer being made, any available components are in limited supply with a price to match, and of course, no readily available blueprints with correct measurements to make your own. All of this makes restoring and maintaining classic cars a lesson in patience, but it doesn’t have to be this way.

With the aid of a 3D scanner capturing accurate measurements of parts and reverse engineering, your replacement has never been easier. If the component is broken, as long as you have all the pieces, you scan and merge them together to make a new complete part. And if you don’t have the piece, you can find someone that does and scan theirs because 3D scanners like the RANGE or POP 2 are highly portable.

Quality Control

When creating new parts for an automobile, using a 3D scanner to quickly check that the new part matches the original CAD design is a massive time saver, rather than manually comparing it. Simply grab your scan, then overlay your 3D model on top of the CAD to see if there are any differences in size.

Take your Car Virtual

Have you ever wanted to add your car to your favorite racing or driving game? Well, with the help of a 3D scanner, it’s possible. Scan the outside and the interior of your car and import them into 3D modeling software to put them together.

Or maybe you’re looking to create a car showroom of the future to let your potential customers virtually explore your fleet from the comfort of their homes.

The Future is Now for 3D Scanning for Automobiles

3D scanners are potent tools for streamlining automobile projects and opening new opportunities for creating replacement parts and virtual models. For the amount of time and money saved, you’d be insane not to use a 3D scanner like the Revopoint RANGE to jumpstart your car modification projects.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.